R&D Design

The company has a professional scientific research team and a production, education, and research devel-opment. The design applications include three-dimensional parametric template and finite element technology template technology and other practical design software. The project-related software includes: design software such as CAD, CATIA, Pro/E, SolidWorks, UG, etc.; analysis software such as ANSYS, ABAQUS , MARC, and NASTRAN, etc.; reconstruction software such as Simpleware, Mimics, Geomagic Studio, etc.

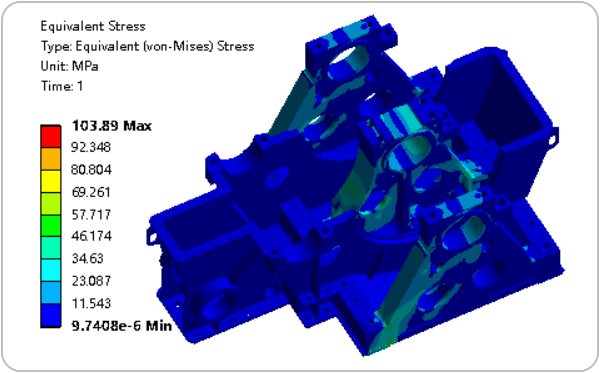

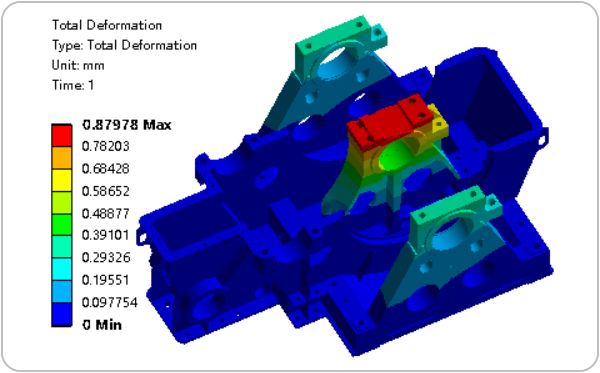

FINITE ELEMENT SIMULATION ANALYSIS

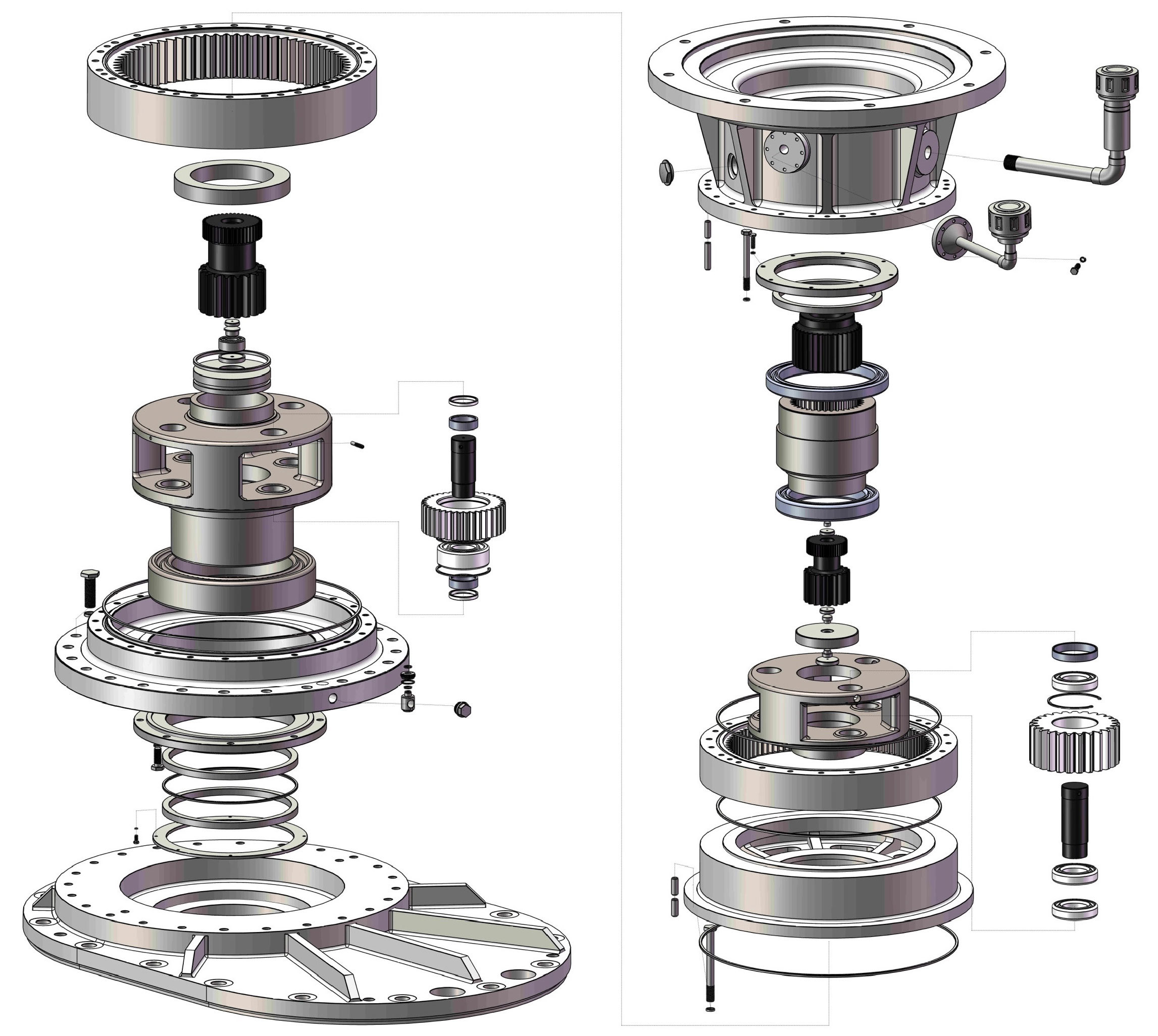

Finite Element Analysis Process: First, establish a three-dimensional digital model of the part ni Solidworks; second, analyze and obtain the loads and constraints of the part during actual working processes; then, import the model into the finite element software ANSYS, add loads and constraints, use tetrahedral mesh division, and establish the finite element model; finally, submit the calculation to obtain the stress and strain conditions of the part, providing guidance for the design, analysis, and optimization of key parts of mining equipment.

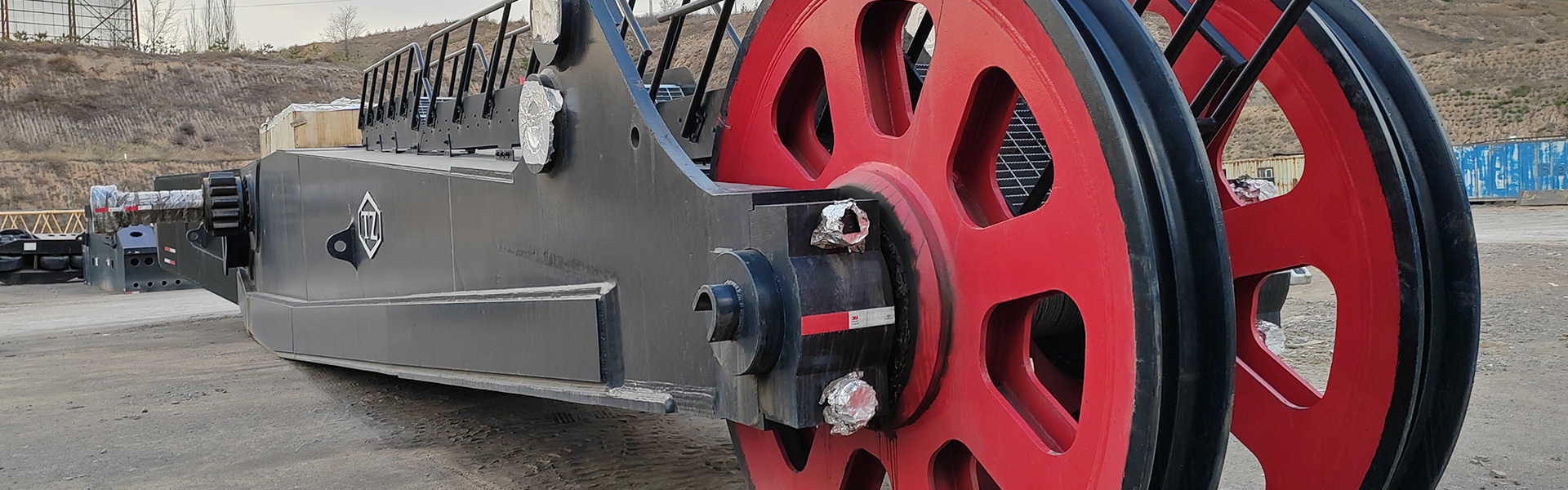

REBUILD AND RE-ENGINEERING

With strong design and survey capabilities to meet user needs, the company regards technology updates as an im-portant business and has received unanimous recognition from users.

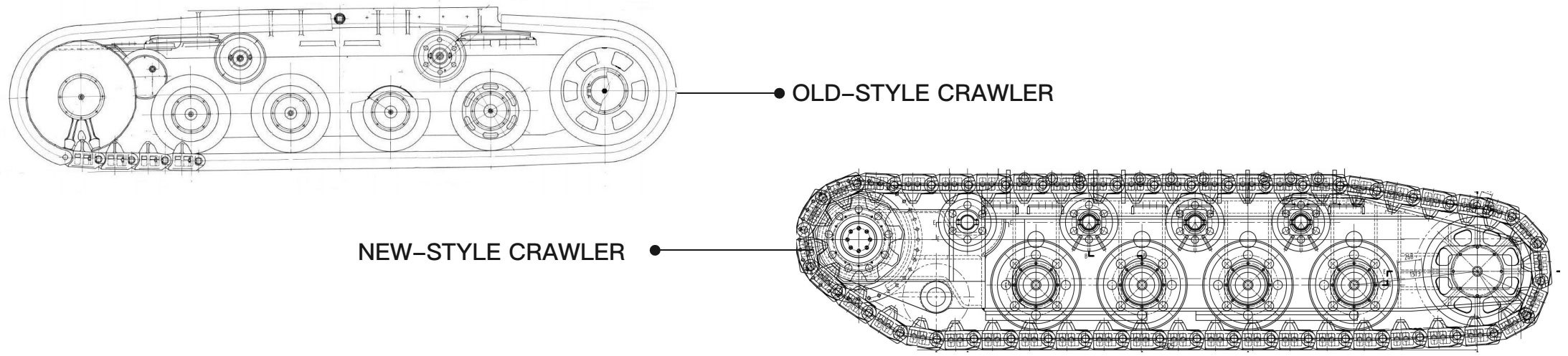

UPGRADE THE ORIGINAL PROPEL SYSTEM

TO AN INDEPENDENT PROPEL SYSTEM

For a certain model of crawler where the original design supports were prone to breaking, this mod-ification focuses on upgrading the support components. The original four small cast supports have been replaced with two large integrated forged supports. This design only involves partial modifications to the walking mechanism, allowing most fo the original components to still be used , thereby reducing the modification cost for the user.

3D DESIGN

Utilize 3D modeling design tools to achieve visual simulation design, improving product practicality and installation accuracy.