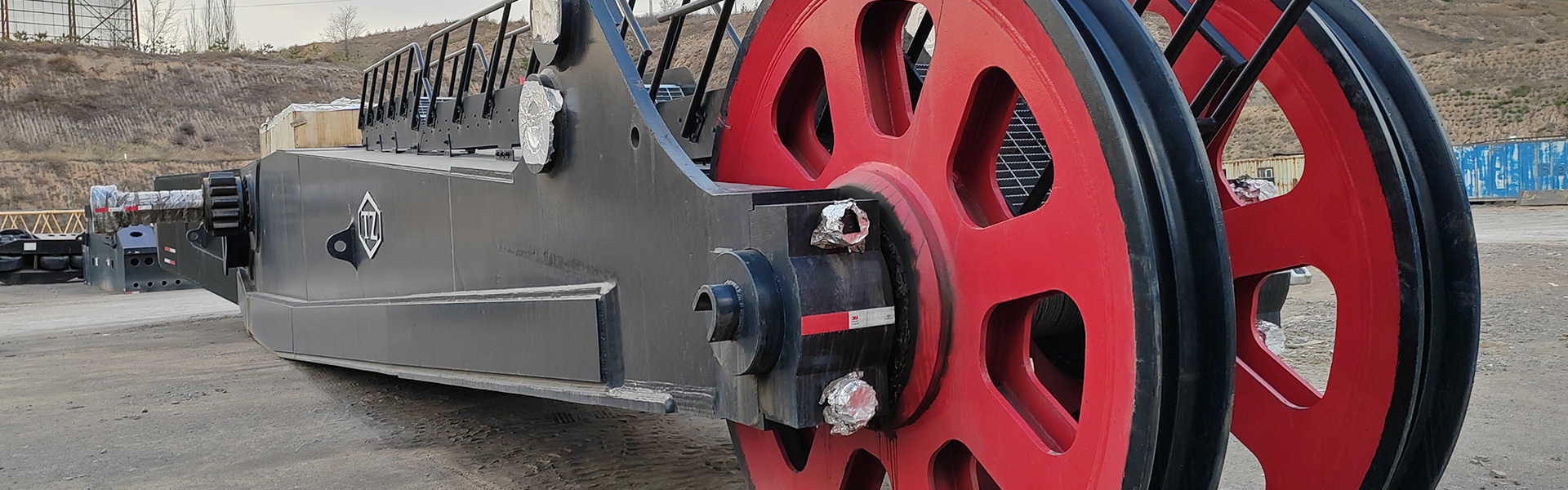

Advanced technology

ADVANCED AND RELIABLE

WELDING PROCEDURE

The company possesses structural component welding manufacturing capabilities and advanced welding processes. Al structural component welding procedures (WPS) are evaluated according to AWS or user-required standards. Welders are evaluated according to AWS or ISO9606-1 standards. Al welders and visual (VT) and non-destructive (NDT) inspection personnel are qualified and certified. The structural component manufacturing process is strictly controlled according to the corresponding procedures and standards to ensure high-quality structural components.

ADVANCED HEATTREATMENT PROCEDURE

The company has the capability for heat treatment of variousparts and a complete heat treatment process. The company owns box-type, well-type high and low-temperature resistance furnaces, vacuumresistance furnaces, high and medium-frequency quenching machinesand a 1800KW variable capacity trolley heat treatment furnace for low-temperature stress relief of large structural parts. Various parts undergonormalizing, annealing, quenching, tempering, quenching andtempering, carburizing, nitriding, carbon-nitrogen co-infiltration hydrogentreatment, and surface quenching treatment, thereby achieving therequired mechanical properties, surface hardness requirements, and long-life performance with minimal stress for welded structural parts.